High performance, low-cost reflow batch oven for use in small lot production and laboratory simulation tests.

The X-Reflow306 was designed for prototyping, laboratory testing, heat-resistance testing and low volume production.

FEATURES

The unit has several unique features:

- Full convection heating with independent control of the front and rear heaters, which enables hot air temperature and time settings in 5 zones and pre-setting of various profiles for different PCB’s.

- The large inspection window allows for monitoring the soldering process during operation (inspection can also be done using a microscope or camera system). Microprocessor-based control uses closed-loop monitoring to ensure absolute repeatability of the temperature profiles and has enough memory to store 250 profiles.

- The large backlit display shows either the specific temperatures and times or a graph of temperature versus time in real time. The Nitrogen Gas inlet is standard and the oven can be used for soldering in a nitrogen environment without requiring any additional hardware.

- The unit has a computer interface for downloading firmware upgrades. This also will enable future custom settings to be downloaded from a PC via the X485-USB Converter.

- The minimum temperature setting is 50°C to accommodate soldering or curing conductive adhesives and other materials that need lower temperatures.

- The PC interface will allow for use of our Windows-based PC Control Program for programming and operating the oven as well as recording the executed profiles on the PC. The schedule for the release of this program is Feb 2020.

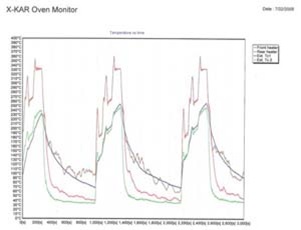

- At present two external thermocouple inputs located on the back panel in conjunction with the optional X-306 Oven Monitor program allow operator to monitor (see the temperature in real time on a PC, save the graph and print it) the board temperature throughout the entire reflow process when using the optional X-306 Oven Monitor program.

- HIGH OPERATING TEMPERATURE for LEAD FREE SOLDERING

The operating temperature of 350°C (662°F), which is higher than other ovens, and better materials ensure performance when soldering with lead free alloys.

- HIGH PERFORMANCE

The X-Reflow306 LF is a low-cost, high-performance production reflow batch oven. This unit has several unique features.

- SMALL DESKTOP SIZE

It has a small footprint and weighs only 43kg. Conventional ovens are large in size, but the X-Reflow306 LF can fit on top of a desk in a small room.

- LARGE GLASS VIEWING WINDOW

The large glass viewing window (280x280mm for the X-Reflow306 LF and 200x200mm for the X-Reflow306 LF-AC) allows for viewing the inside of the heating chamber and observing the heated object. Users can see and check or photograph the details of a soldering process by using a microscope or camera.

- LARGE BACKLIT LCD DISPLAY WITH DIGITAL PROGRAM AND GRAPHIC PROFILE INFORMATION

The large backlit LCD display allows easy program entry and verification. Pressing one key can change the temperature numeric profile into a graph display to allow easy checking of the operating conditions at a glance. Depending on the working area, the LCD display brightness can be adjusted by the contrast adjustment in the settings menu.

- CAPACITY TO STORE UP TO 250 PROGRAMS

The oven has five operation zones- preheat 1, preheat 2, Soak, Reflow and Cooling. Each zone has defined a desired temperature and the time in which to reach and maintain this temperature. There is an additional purging zone when soldering in inert gas environment. Up to 250 such programs can be stored in the unit’s memory and recalled when needed.

Each Program can be specific to the PCB size and construction (number of layers), type of solder paste used for the process, mounting density, component size and mass etc.

- INDEPENDENT CONTROL OF THE FRONT AND REAR HEATERS

If the thermal load on the board is not distributed symmetrically, the operator can independently control the temperature of the front and back heaters.

- TIME ZONE LED (Operation LEDs)

The profile drawing and current zone LEDs on the front panel allow progress to be checked at a glance.

- N2 PORT

To decrease the oxidation of leads, pads, and the solder during soldering, a compressed N2 gas source can be connected to the oven to replace the air (oxygen).

- MANAGEMENT CONTROL OF THE PRE-PROGRAMMED PROFILES

The oven has password protection. This allows for enabling/disabling programming of the profiles and entering changes to them.

- SEQUENCER MODE (Another UNIQUE Feature)

For manufacturers of laminates who make PCBs which have to temperature cycle samples of the material (This means bringing the material to a required temperature following a recommended profile and then cooling it to room temperature) several times, the X-Reflow306 LF-AC has a special mode of operation called SEQUENCER. In this mode, the operator can pre-program a sequence of up to eight Programs and the low-end temperature to which the board needs to be cooled to. The oven will execute the sequence semi-automatically. It will run the first program, vent the fumes from the oven, prompt the operator to lift the clamshell top, cool the heated specimen to the pre-programmed temperature and prompt the Operator to close the clamshell top and press ENTER to start the next cycle.

- INTERFACE with a PC

The unit is equipped with an interface to a PC (connection to a PC via an XKAR X485-USB converter) to enable firmware upgrades, use of the X-KAR Oven Monitor program to see and document the real temperature on the processed PCB, and, in the future, control the oven from a PC.

- ACCELERATED, ADVANCED COOLING SYSTEM (X-Reflow306 LF-AC model only)

The Advanced Cooling System in the X-Reflow306 LF-AC model, when connected to a pressurized air source (known as shop air) cools the soldered PCB's at a much quicker rate than is possible in regular ovens. This provides better reliability of soldering connections and better safety for the Operators handling the boards.

- INTELLIGENT AND UNIQUE FUME EXTRACTION MANAGEMENT

Each X-Reflow306 LF, like no other oven in the industry, is equipped with the Proprietary Fumes Cooling System and a program-controlled power outlet for the fume extractor. This makes it possible to connect and start the Fume Extractor at the end of the Reflow Zone when the oven is still closed and extract the fumes before the oven is opened. The timing of when it starts and how long the fume extractor will work is controlled by the oven administrator who can control this in the settings MENU. This way the fumes do not mix with air in the room and can be extracted through a HEPA-type high vacuum fume extractor. (The X-KAR Brand offers X-306 FumeExtract for this purpose).

|